CWRU Motorsports

Overview

I’m currently the suspension and steering lead CWRU Motorsports. I lead a team of student engineers to design and construct these subsystems. Each year CWRU Motorsports designs and manufactures a single seat off-road race cars to compete in Baja SAE competitions against other universities. To learn more about the team, check out our website.

Projects

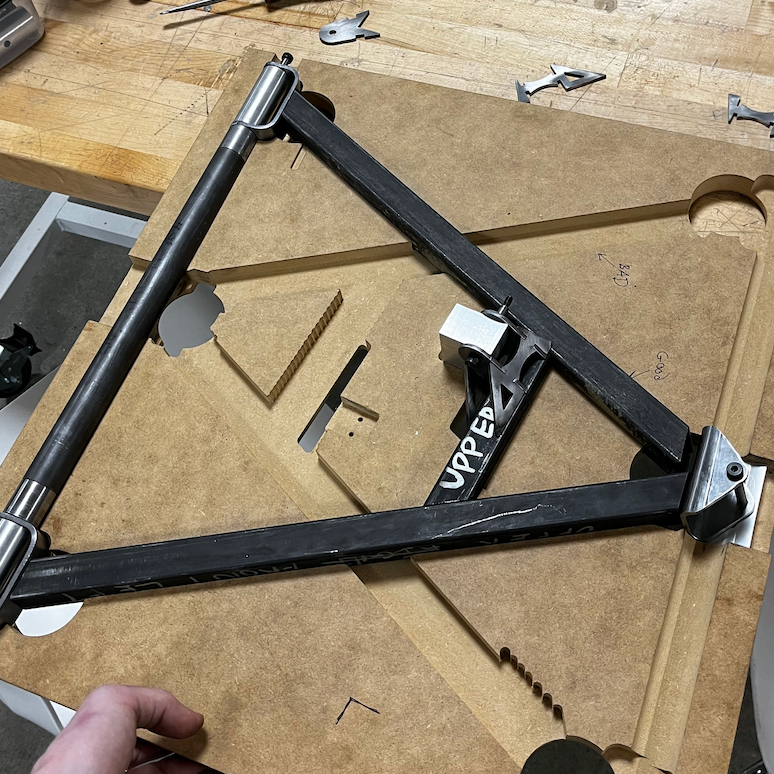

Suspension Arms

Part Design and Validation